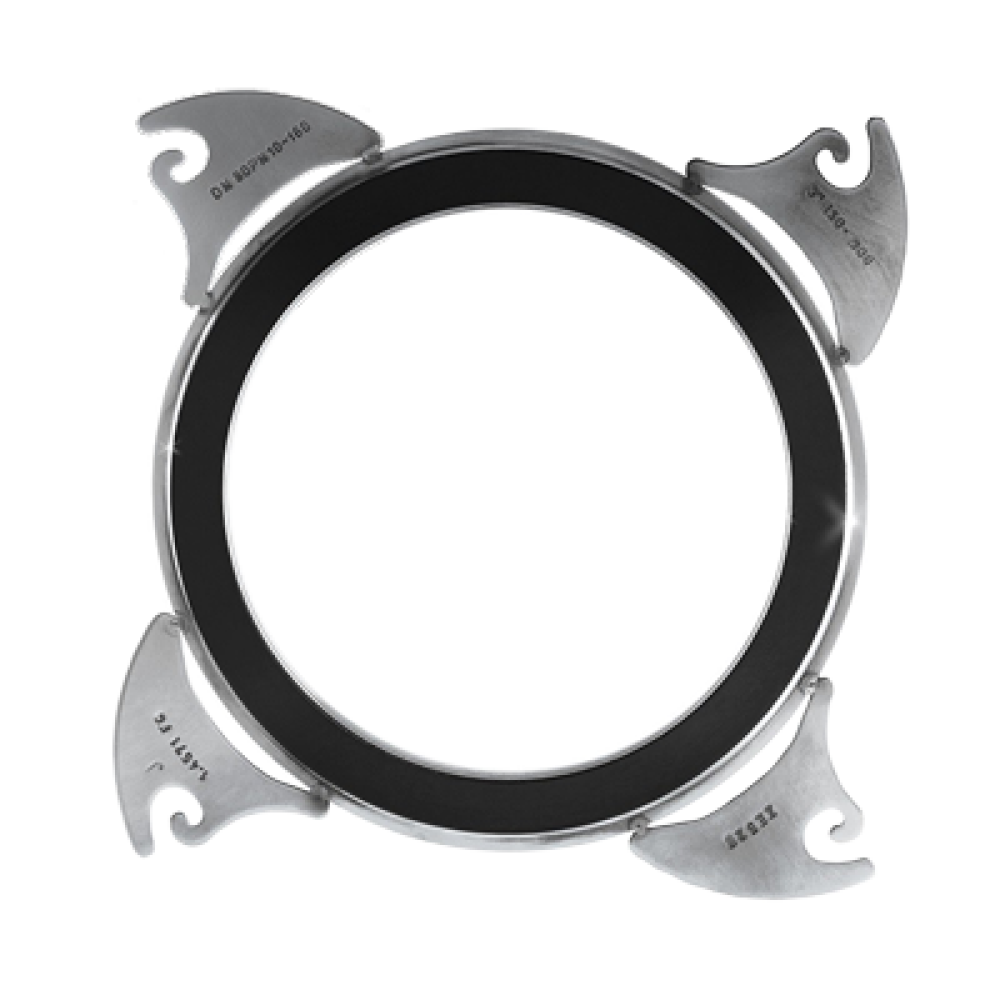

Spectacle Blind

Description:

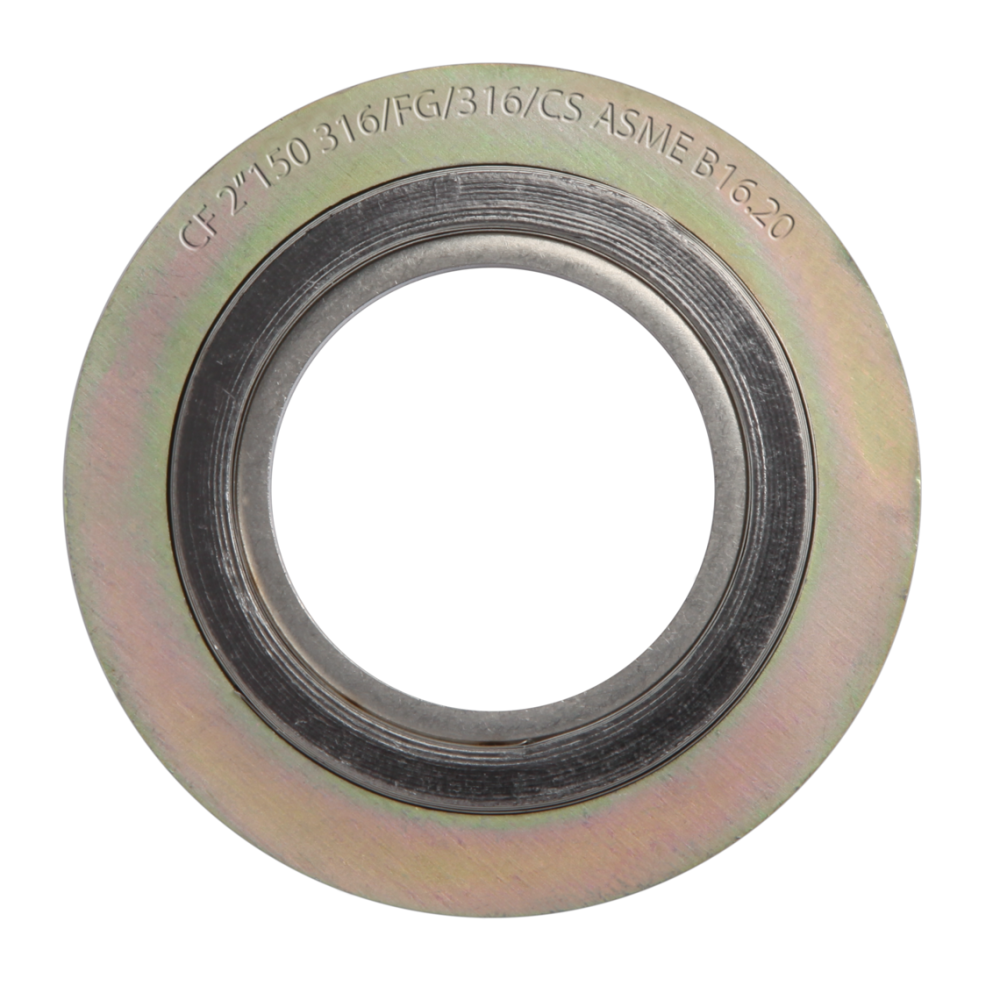

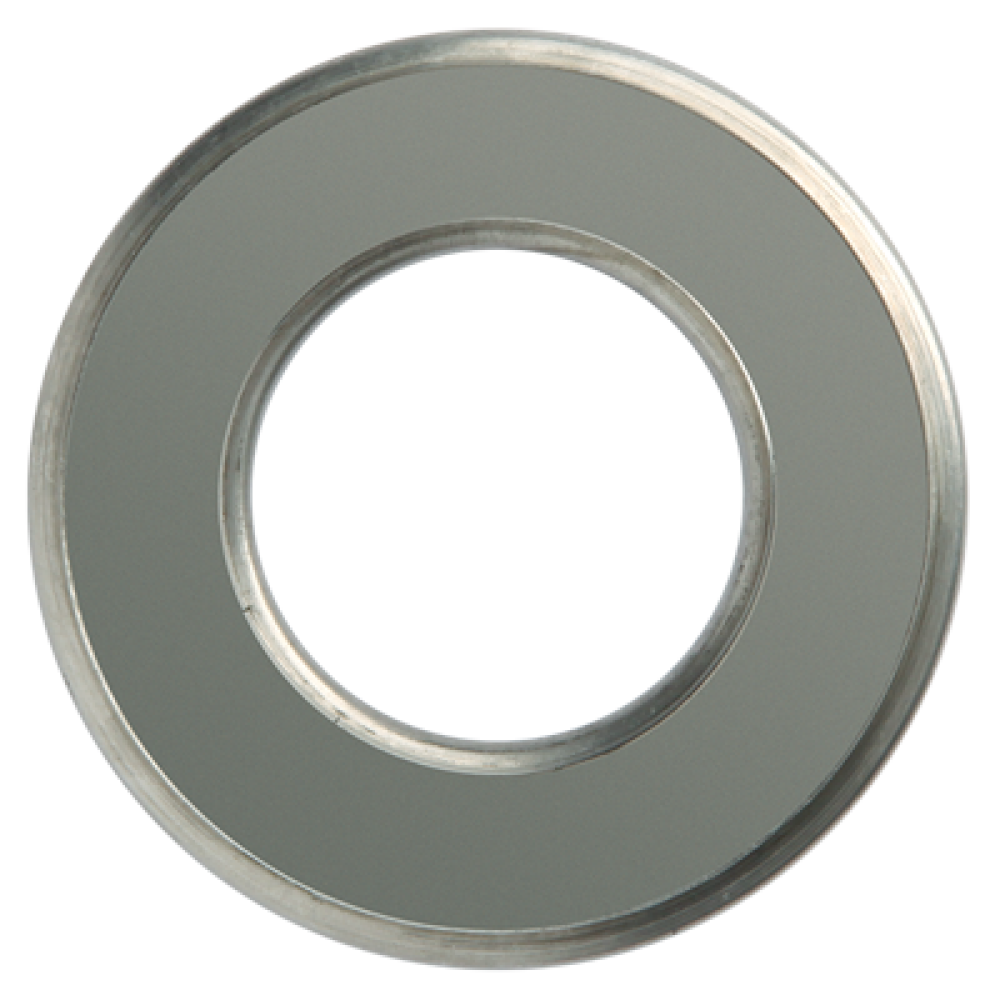

Spectacle Blind are created and engineerd by CF Service technical department according to your specific needs. The CF Service Spectacle Blind are available in different materials and dimensions and they are manufactured in two parts: the blind side and the sealing side. Our taylor made solutions are suitable also with a special grooved sealing surfaceMore Information

Contact us for more information

-

TECHNICAL FEATURES

- Metal parts: Stainless Steel 304 T max 550 °C | Stainless Steel 316/L/Ti T max 550 °C | Stainless Steel 321 T max 550 °C | Alloy 400, 600, 800, 825: T max 600 – 950 °C | Hastelloy C276, B2 T max 450 °C | Titanium T max 350 °C

flexible, resistant to almost all chemicals, environmentally friendly, wide operating temperature range, resistant to aging, lasting stability under load and constant elastic recovery even with changes in temperature, does not generate creep or cold flow, resistant to high pressures, good thermal and electrical conductivity, easy to cut and punch.

Our Catalogs