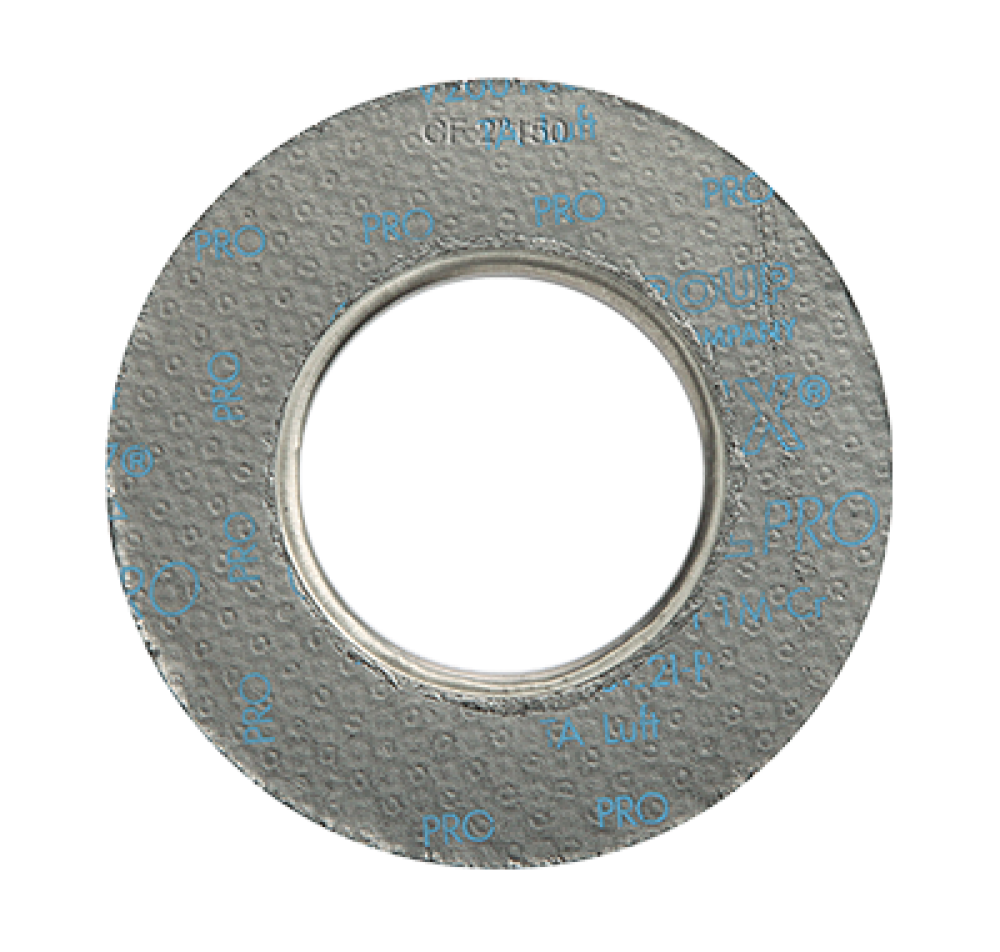

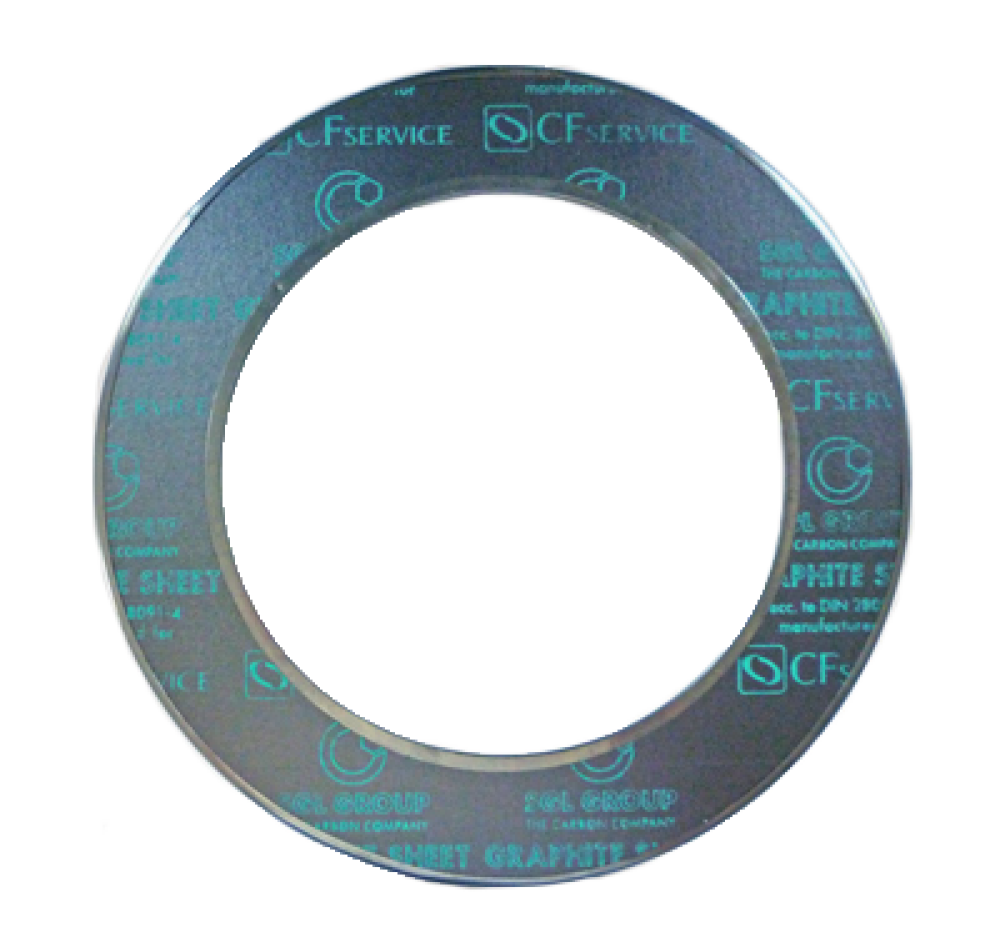

SIGRAFLEX® HOCHDRUCK PRO

Description:

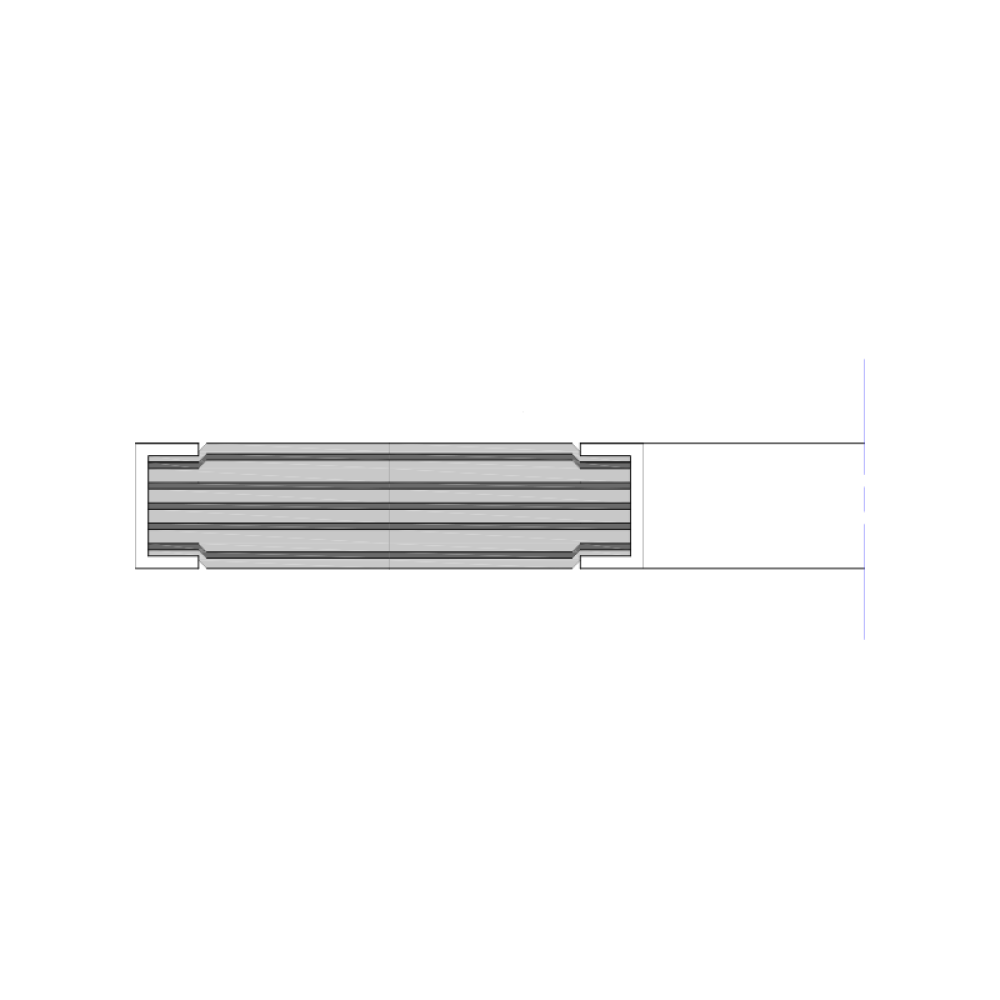

SIGRAFLEX® HOCKDRUCK PRO (SGL Carbon patent) is composed of expanded graphite sheets impregnated with corrosion inhibitor, purity > 99.85% and smooth sheets in AISI 316L steel of 0.05mm.It can be installed in the presence of surface pressures up to 400 N / mm^2 and operating pressures up to 250 bar.

The main characteristics are: very high pressure resistance, high resistance to bursting, high rigidity, compression stability, good elastic return over time, wide thermal resistance.

- Ideal for use at high temperatures and pressures and with R45 substances

- High compressive strength value

- Meets the Atex requirements (CEI 31-35 guide)

- Graphite with a purity of 99.85%

More Information

Contact us for more information

-

TECHNICAL FEATURES

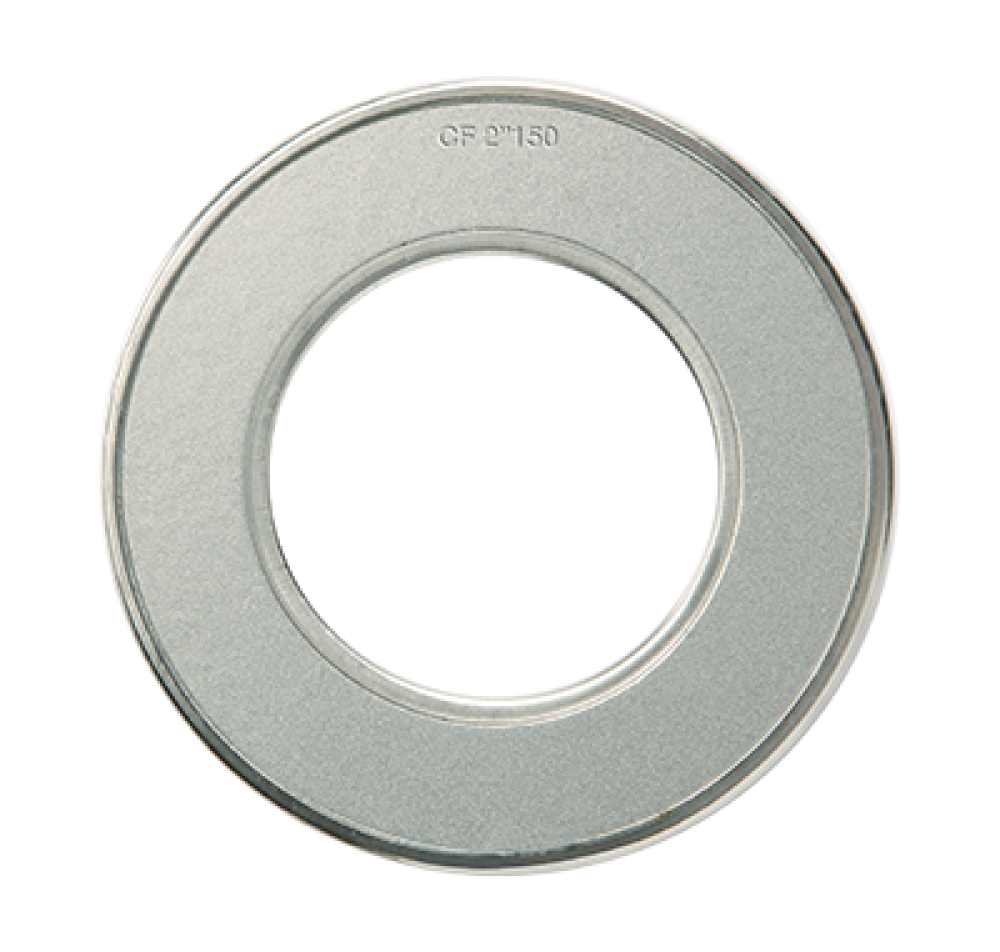

- Metal part: Smooth sheets in AISI 316L

- Cover material for metal part faces: Expanded graphite with density equal to 1.1 g / cm³ | Ash content less than 0.15% | Chloride content less than 10 ppm | Cold compressibility 30 - 40% | Gas permeability 0.06 mg/ms

- Loss rate according to VDI 2440: 2.3*10^-5 mbar l/ms

- Compressive strength: 400 MPa

- Characteristic sealing values (DIN 28090): svu/0.1 for internal pressure of 10 Bar = 10 N/mm² m= 1.3

- Gasket factors (ASTM): m factor= 2.5 | y factor= 2000 psi (13.79 MPa)

- Temperature/pressure range: Temperature: – 250 °C + 550 °C | Pressure: vacuum to 250 bar

- Approvals: Ta-Luft VDI2440 | Fire Safety certificate according to API 607 | BAM approved for use on oxygen and explosive atmospheres | DVGW certified (according to DIN 3535-6) | TUV Blow out test certificate

Our Catalogs